Low-Velocity Sprayed Mortars: A Complement to Shotcrete in Concrete Repair

As concrete infrastructure continues to age, the demand for efficient, durable, and cost-effective repair solutions is on the rise. Among the most trusted techniques for restoring damaged concrete is shotcrete — a high-velocity, pneumatically placed mortar or concrete known for its excellent reinforcement encapsulation and structural performance.

But as material science and application methods evolve, a new approach has emerged for select use cases: Low-Velocity Sprayed Mortar (LVSM).

What is LVSM?

Shotcrete

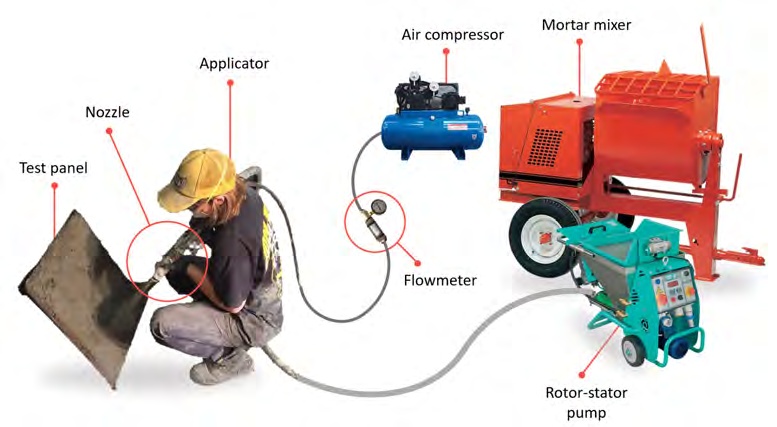

LVSM refers to the spray application of fully mixed mortar at low pressures. Unlike traditional shotcrete, which relies on high-speed delivery to consolidate material, LVSM uses reduced velocity, resulting in significantly less rebound, lower dust, and a softer spray impact. These traits make it well-suited for non-structural concrete repairs, architectural refinishing, or surface patching.

Key Advantages of LVSM vs. Shotcrete

In controlled testing environments, LVSM has shown promising results when compared to wet-mix shotcrete:

-

Compressive Strength: Exceeds 60 MPa — comparable to structural shotcrete.

-

Bond Strength: Over 2.0 MPa in pull-off tests on properly prepared substrates.

-

Durability: Excellent resistance to freeze-thaw cycles and chloride penetration.

-

Rebound Loss: Minimal, reducing waste and cleanup.

-

Porosity & Absorption: Slightly higher than shotcrete but still acceptable for many surface repair jobs.

For clients interested in architectural finishes or refined patchwork in sensitive environments, LVSM offers a new dimension of flexibility.

Limitations and Use Cases

Despite its benefits, LVSM has important limitations — especially in structural contexts. Its lower impact velocity makes it less effective at encapsulating reinforcing bars, and it’s limited to thin layers (under 50 mm) per pass.

Operators must maintain close proximity (~0.3 m) to the work surface and apply the material using a consistent, circular spray pattern. In the absence of standardized industry certifications, the experience and precision of the applicator play a crucial role in successful outcomes — something Boulderscape prioritizes with every client engagement.

Ideal Scenarios for LVSM

Low-Velocity Sprayed Mortar is best suited for:

-

Surface patching without embedded reinforcement

-

Thin vertical or overhead repairs

-

Restoration work where rebound must be minimized

-

Aesthetic concrete treatments in public spaces

-

Lightweight architectural detailing

However, for deep-section repairs, slope stabilization, or soil nail wall applications, traditional shotcrete remains the preferred and proven method.

The Future of Concrete Repair

While LVSM is still an emerging technique, it represents a valuable addition to the contractor’s toolkit — especially when paired with Boulderscape’s decades of field-proven experience. As innovations in mortar rheology and delivery systems advance, hybrid approaches that blend the control of LVSM with the force of shotcrete may offer new possibilities in precision repair and artistic application.

Until then, success in concrete restoration depends on knowing the right material for the job, and having the experts who can apply it with both skill and vision.

Ready to explore innovative repair strategies? Request a quote or contact our team to discuss how we can help you achieve long-lasting, beautiful concrete solutions.

Contact Boulderscape, Inc.

Address: 1050 Calle Negocio, San Clemente, CA 92673

Office: (949) 661-5087 | Fax: (949) 661-3397

Website: www.Boulderscape.com

“Installers of more than 14 million square feet of structural/architectural shotcrete nationwide”